The fundamental difference between barcode printers and label printers is how they print. Both printers have their own advantages, which also determine their different usage scenarios. Next, we will start with the printing methods of these two printers and their respective advantages. Today, let's talk about the difference between them:

The printer that prints barcodes is thermal based and there are two types: thermal printing and thermal transfer printing:

1. The consumables used in thermal printing are thermal paper, which is coated with a coating and will change color when heated, similar to photographic film. This coating will change color when heated, and the heated print head acts directly on the thermal paper, so the printed media will not be stored for a long time, usually half a year!

2. Thermal transfer printers use a special carbon ribbon to heat the toner coating on the ribbon and transfer it to paper or other materials, where the intermediate medium is the ribbon. Print media can be stored for a long time, generally more than two years. The printed content is generally corporate brand logo, serial number logo, packaging logo, barcode logo, envelope label, clothing tag, etc.

The printer uses the thermal transfer technology described above to print the labels. Simply put, it is to use a special carbon ribbon to thermally transfer the toner coating on the carbon ribbon to paper or other materials through the working principle of a fax print head, because the coating material on the carbon ribbon can be used as required. selection, resulting in strong adhesion. In addition, the choice of printing medium can ensure that the printed handwriting is not affected by the outside world.

Advantages of barcode printers

☆Even if only one sheet of paper is used, a small amount of diversified printing can be done without waste.

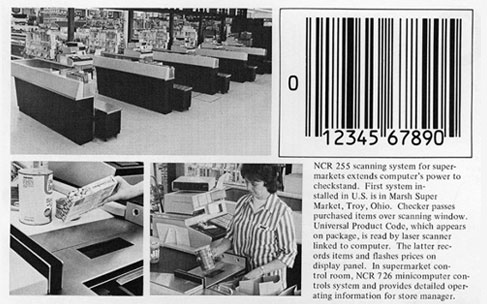

☆Using the advantages of barcodes and scanners to reduce manual processing time and costs.

☆You can print all kinds of graphics according to your needs, especially the company logo and certification logo.

☆You can print the serial number and track the product.

☆You can connect to the company's database data, quickly extract and print data.

☆It can be applied to the production line to track product production at any time and avoid excess material.

☆It can be applied to warehouse management to keep abreast of the latest inventory situation.

☆It can print tickets or various bills at high speed and high quality.

☆According to needs, you can choose labels with high temperature resistance, corrosion resistance or strong adhesion for printing.

☆It can print very fast with a length of 15cm per second.

☆It can be used with the cutter to cut out immediately for bill editing. The printed content and printing effect are not inferior.

☆Using system integration solutions to comprehensively improve management systems such as procurement, production, warehousing, logistics, and sales. Using barcode labels as the medium.

Advantages of printers

★Fast printing speed: General printers can only print up to 10 sheets of paper per minute, while label printers can print more than 300 labels per minute.

★Paper feeding device specially designed for printing labels: The feeding paper is in a roll shape, and the paper feeding form is in a roll shape, so that it can continue to print after loading thousands of sheets.

★Thermal transfer printing: By choosing the right material, the effect of scratch resistance, high temperature resistance, abrasion resistance and even solvent resistance can be achieved.

★Special paper feeding mode, which can print ticket cards, tags and other special specification paper.

★Can be printed on fabric.

★Professional steel structure, suitable for continuous printing for hours.