Product Introduction

Sucetong KS series desktop automatic weighing and measuring volume system integrates barcode, weight, volume information automatic collection and input system, and prints face sheets in real time with printer.

High speed, high efficiency, and small footprint. The system operation is simple and clear, easy to learn and understand, make full use of the generated information resources, reduce the workload of information entry, and reduce the labor intensity of operators.

HSJ-Sucetong KS-04 automatic scanning code weighing and sorting equipment adopts industrial scanning code camera and industrial pressure sensor, which is stable and reliable. It can realize the functions of barcode scanning, weighing, sorting and data uploading of regular and irregular goods. It has simplified design, small footprint, powerful functions, and high sorting efficiency. It is a good assistant for logistics enterprises sorting!

Second beat second scan, one minute two electric drum sorting, accurate and efficient, ±1g average measurement accuracy, sorting efficiency of 1800-2500 pieces/hour.

Product Features

Function customization and features

Function customization:

According to your needs, you can customize functions such as high-definition pictures, barcode visualization, picture naming, object shape classification, and condition restrictions.

Features:

Sucetong HSJ-KS04 has the automatic sorting function of electric drum and belt, the data can be stored immediately after measurement, and the data can be exported at any time, accurate to any time; it is suitable for the measurement of small and medium-sized products, regular/irregular, and the workbench can be arbitrarily Placement can be used in scenarios such as logistics sorting and factory manufacturing lines.

Product composition:

Integrated welding paint rack, TPC6000-integrated industrial control host (mouse/keyboard/power adapter), one set of Hikvision smart camera, weighing system (one static scale/meter), 1.8M multi-hole socket, 3D visual body measuring camera (optional).

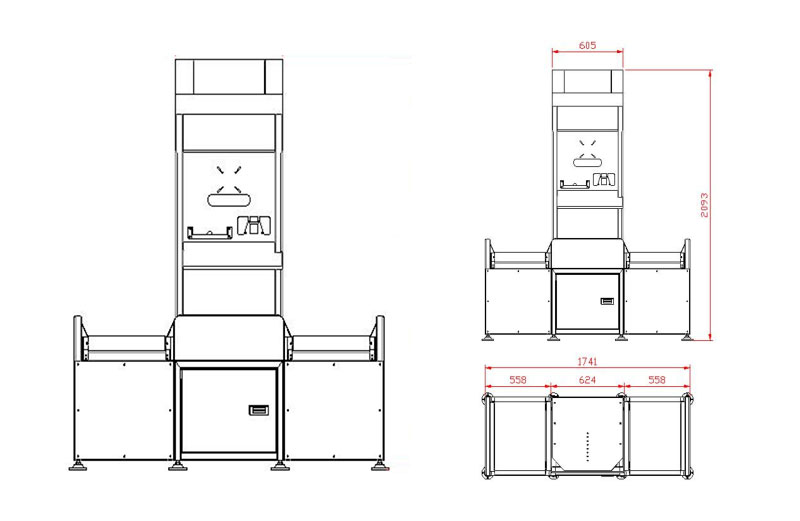

Structure size (can be customized):

Product parameters

| Device name | HSJ-Sucetong-HSJ-KS04 |

| Scanning equipment | Industrial code scanning smart camera (optional 3D camera) |

| Measurement principle | Scan code weighing measurement |

| Measure size | Maximum 500*400*400MM Minimum 100*100*10MM |

| Equipment size | 1741MM*619MM*2092MM |

| Weight accuracy | ±1g |

| Measuring speed | 1800-2500 pieces/hour |

| Data output | Excel/Http/Websocket,Serial port optional (interface RS232) |

| Machine power | 220V 800W |

| Measure weight | 5g~6000g |

| Scan code | Hikvision Industrial Camera |

| Package type | Regular/Irregular/Shaped/Thin |

| Placement requirements | Arbitrary placement |

| Super thin object | Support thin parts measurement |

| Supported formats | Data upload, photo storage, system docking, barcode filtering, abnormal handling of super long pieces, network transmission |

| Tape removal | Support |

| System Support | Windows10 |

| Working temperature and humidity | -5~40℃ / 0-80% |

| Multi-language | support multi-language |

After-sales service

| Honorary customer | Yuantong Express, Debon Logistics, Yunda Express, Jingdong Logistics, Export Easy Logistics, Yida International Logistics, etc. |

| Delivery period | About 15 working days for equipment production + software debugging (excluding shipping time and time required for custom hardware) |

| Warranty time | 1. If the main unit of the product has a performance failure due to non-human damage, seven-day free return, replacement, and warranty; 15-day free replacement and warranty; one-year warranty; 2. The product software has a performance failure due to non-human damage, and the product will be delivered for free within one year. Update the product system software; 3. Within the scope of the warranty, if the whole machine is replaced (excluding accessories), the warranty period of the replaced product will be recalculated according to the Three Guarantees Law; 4. Gifts and accessories do not participate in the warranty; |

| After-sale warranty | If the customer finds a problem, the on-site personnel can feedback the problem to the person in charge of the project in the computer department, and then the person in charge will contact our technical staff. We will give you a reply within four hours and deal with it within 48 hours (48 hours is in Shenzhen. In the urban area, other areas will be processed within 54 hours) Open 24-hour after-sales service hotline: +86-13316986889 |

Popular Products

Popular Products