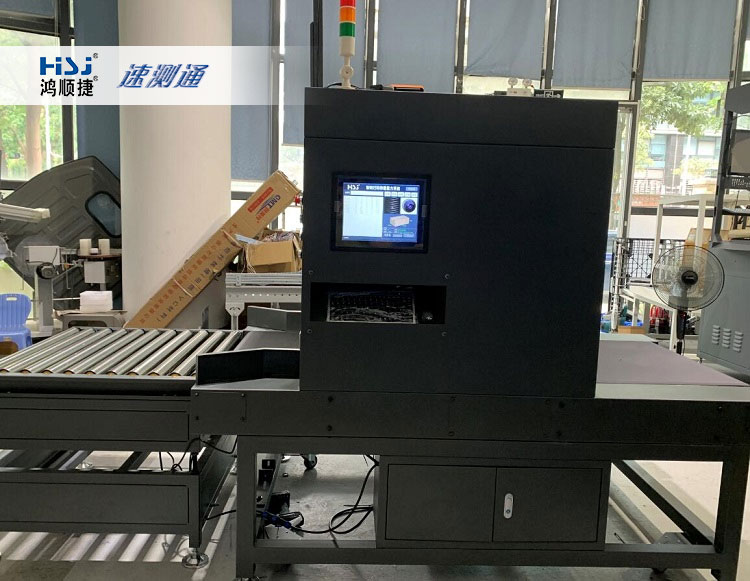

Sucetong Intelligent Automatic Scan Code Weighing Weight Volume Sorting System,

The main functions of the system are as follows: the logistics center receives thousands of express parcels sent by hundreds of suppliers or shippers through various means of transportation every day, unloads these parcels in the shortest time and goes to the destination of the parcels Quickly and accurately classify the destination of these packages, scan the code, weigh, measure the volume, record the packing and channel information, pack and print the box label for loading and delivery.

1. Hardware equipment: Matrix sorting module is adopted, the electric control adopts Mitsubishi PLC control and MODBUS communication protocol, servo motor controls the belt line and sorting module for mechanical movement, equipped with Hikvision industrial-grade high-definition code scanning camera, DWS high-definition 3D measuring camera (or high-precision grating measuring instrument), dynamic electronic scale, Omron photoelectric sensor

1. Software functions:

a. PLC communication protocol and command docking, data analysis and display (equipment operation information, alarm information, data information)

b. The equipment adopts RS232/485 data communication for IO control, alarm output, equipment operation and shutdown

c. Sorting data record, package data (barcode, volume, weight) upload, sorting channel confirmation and equipment action

d. The sorting channel is full of bags, abnormal detection, system prompts and alarms

e. The logistics sorting system adopts TCP/IP communication protocol for docking and data interaction

f. Zebra/TSC printer docking, sealing bag, box label printing